India News

Buying fighter jets from abroad cheaper than manufacturing them at HAL, says Def Min

Manufacturing fighter jets at India’s public sector unit Hindustan Aeronautics Limited (HAL) is costlier than buying them from the the original equipment manufacturer (OEM) abroad, according to a defence ministry audit, reported The Hindustan Times (HT).

The report comes at a time when there is a raging controversy over Modi government dumping a deal being negotiated with Dassault Aviation of France for 126 Rafale jets, 108 of which were to be made in India by HAL, and going instead for a purchase of 36 fighter jets in fly-away condition with Anil Ambani’s Reliance Defence getting the offset contract.

The department of defence production is studying the document, said an officer aware of the development told HT.

The document, reported HT, says that Su-30MKI – the mainstay fighters of the Indian Air Force (IAF) which is manufactured by HAL under licence from Russia – is about Rs 150 crore costlier than the ones made in Russia.

A Su-30MKI made in Russia cost Rs 269.77 crore whereas one made by HAL in India costs Rs 417.69 crore, almost “Rs 150 crore” more per aircraft, the review said.

Similarly, there is a huge cost difference between the cost of the Hawk trainer aircraft manufactured by British Aerospace and those made HAL.

After long and torturous negotiations, India bought British made Hawk jets to train pilots in 2004. Of the initial 62 Hawk jets, 24 were to be bought in a fly-away condition and the remaining were to be manufactured under licence by HAL. Each Hawk aircraft manufactured Britain in 2004 cost Rs 78 Crore. Those manufactured at HAL would have cost Rs 88 crore that year. The cost Hawk aircraft produced by HAL continued to increase. In 2010, the cost shot-up to Rs 98 crore and in 2016, Rs 153 crore.

The difference in price “is primarily due to lesser efficiency and exorbitant man hour rates,” the review has found.

The purchase of 126 Medium Multi-Role Rafale fighters being negotiated by the previous government, 108 would have been assembled in India by HAL, was scrapped because of high man hour cost at HAL, which would have needed 2.7 times more man-hours than the French company for each aircraft, said the HT report.

HAL disagreed with the interpretation of the report. Responding to queries, a spokesperson told HT, “Cost escalation from 2005 (for the Hawk jet) is normal. We also need to take into account the life-cycle cost of each product against off the shelf purchase from overseas.”

“The indigenous benefits, the ecosystem HAL creates for the larger benefit of the country should be factored in also. Importantly, staggered or small orders deny economies of scale to HAL,” said the spokesperson.

HAL also pointed to supply chain issues adding to cost. “Given that multiple agencies get involved in our manufacturing process, kit cost from OEMs and other delays like raw material and spare part supply issues, which are also endemic to the aerospace industry in India, the increase in cost must be evaluated in the right spirit,” the spokesperson added.

2024 Lok Sabha Elections

Lok Sabha election 2024: Nearly 50% voter turnout recorded in second phase till 3 pm

The constituencies going to polls today include all 20 Lok Sabha seats in Kerala, 14 in Karnataka, 13 in Rajasthan, and others spread across different states.

In the second phase of Lok Sabha elections 2024, over 50% of voters were registered in 13 states and the UTs till 3 p.m. 65% of voters participated in the first round of the Lok Sabha elections.

The 18th Lok Sabha elections are currently in their second phase, with voting for 88 seats taking place across 13 states and union territories. There are more than 1,200 people running for office, four of them are from outside Manipur.

Union minister Rajeev Chandrasekhar, BJP members Tejasvi Surya, Hema Malini, and Arun Govil, Rahul Gandhi and Congress leader Shashi Tharoor, DK Suresh, the brother of Karnataka Deputy Chief Minister DK Shivakumar, and former chief minister HD Kumaraswamy are among the notable contenders for the second phase.

In 2019, the NDA had won 56 of the 89 seats and the UPA 24. Six of these seats have been redrawn as part of the delimitation exercise.

The first phase of the seven stages of the elections took place on Friday, including 102 seats spread across 21 states and Union territories. Voter turnout was about 65.5% in the first phase, according to the reports.

In biggest festival of democracy, people from all walks of sector took part in it. A video went viral where former India captain and current Indian team head coach Rahul Dravid and former India player and head coach Anil Kumble were seen standing in line to cast their vote.

Meanwhile, voting started at 7 a.m. and will end at 6 p.m. The Election Commission has extended voting hours for those who are in line by an hour. According to Election Commission figures, the first two hours saw a 9.3% voter turnout throughout the 88 constituencies. By 9 am, Kerala had recorded 8.52%, Karnataka 9.21%, and Madhya Pradesh 13.82%.

In this phase, there were about 15.88 crore eligible voters, comprising 5.929 third-gender electors, 8.08 crore males, and 7.8 crore women. 3.28 crore young voters, aged 20 to 29, are among them; 34.8 lakh of them are first-time voters.

2024 Lok Sabha Elections

Lok Sabha elections 2024: 102-year-old man walks to polling booth to cast his vote in Jammu

The lowest voter turnout so far was noted in Ramgarh at 1.53%.

A 102-year-old man showed up at a Jammu polling place to cast his vote in the second phase of the Lok Sabha elections on Friday. Haji Karam Din arrived at the Reasi district polling place in the Jammu constituency with a walking stick in hand and a family member who assisted him with the pre-voting process.

Haji Karam Din, who is 102-year-old, showed his inked finger and posed for pictures outside the polling booth after casting his vote. He said voting at this polling place at this age makes him very happy. He has always cast his vote. Even at the age of 102, this experience is still ongoing, he said.

Reasi district is a part of the Jammu parliamentary constituency, and 22 candidates are up for vote with around 17.81 lakh eligible voters.

BJP’s sitting member Jugal Kishore Sharma is aiming for a third term in office following wins in the elections of 2014 and 2019. Former minister and Congress candidate Raman Bhalla is his main opponent.

Voting in the Jammu-Reasi Lok Sabha constituency began with eager voters showing up at the polling places. Some of them were wearing traditional Dogra attire.

In 2,416 polling places around the constituency, voting got underway at 7 a.m., and 10.39% of the total votes were cast by 9 a.m. In the 2019 Lok Sabha elections, Jammu recorded a 74% voter turnout.

Following the repeal of Article 370 and the division of the former state into two Union Territories five years ago, this is Jammu’s first significant election.

The Akhnoor segment received the highest percentage of votes, 14.24%, followed by Reasi (14.13%), Gulabgarh (13.53%), Shri Mata Vaishnodevi (12.71%), Marh (12.31%), Samba (8.56%), R S Pura Jammu South (8.17%), and Suchetgarh (5.67%), according to the officials. Ramgarh recorded the lowest voter participation of 1.53% so far.

Low attendance was observed in the border areas of the districts of Jammu and Samba till nine in the morning, according to poll data.

The officials said that big lines of voters were observed at several polling places throughout Jammu city. Voters were observed heading towards polling places early in the morning.

India News

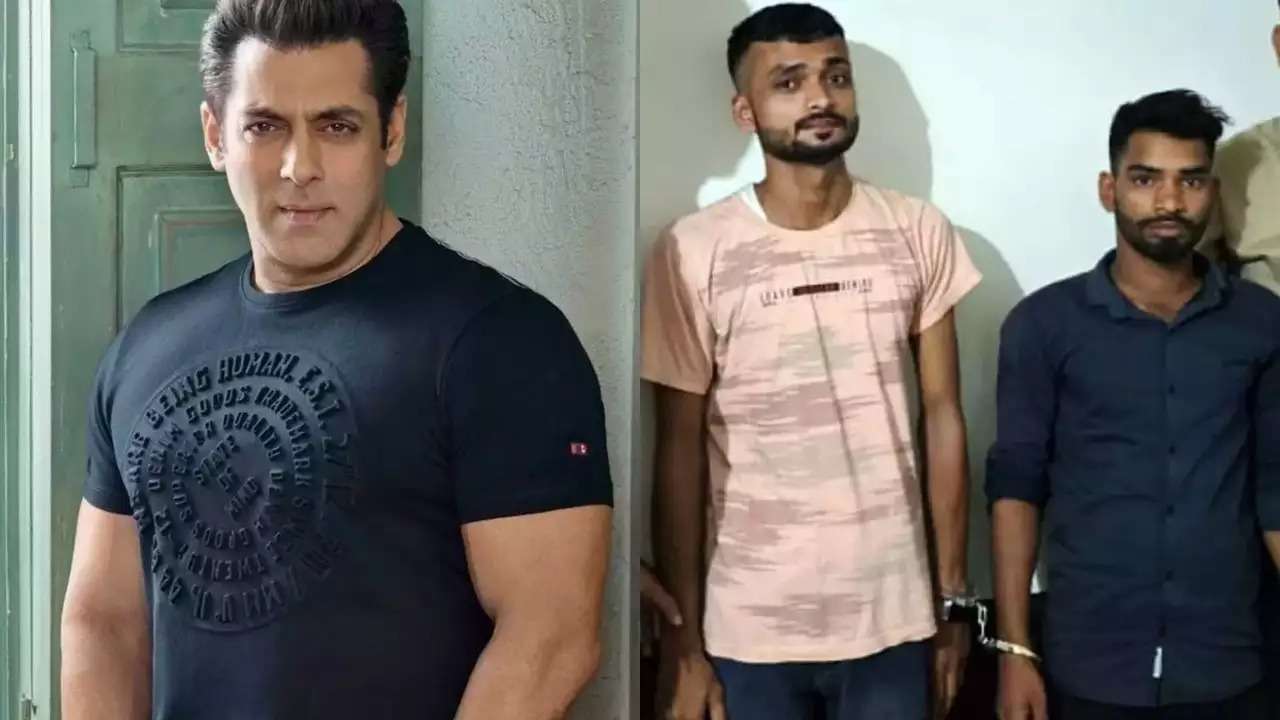

Salman Khan house firing case: NIA interrogates arrested shooters Sagar Pal, Vicky Gupta for three hours

The investigation into the shocking firing incident that took place outside Salman Khan’s house on April 14 keeps bringing new updates with every passing day. In this case, Sagar Pal and Vicky Gupta, the two suspected shooters, have already been taken into custody.

The two shooters have reportedly been questioned by the National Investigation Agency (NIA), according to a new development. Every day that goes by, more information is revealed about the inquiry into the shocking firing incident that happened outside Salman Khan’s house on April 14. Sagar Pal and Vicky Gupta, the two accused shooters, are being held in custody after their first arrests.

It was recently discovered that the two shooters were questioned by the National Investigation Agency (NIA).

NIA has reportedly begun questioning Sagar Pal and Vicky Gupta, who were detained a few days ago for firing openly outside Salman Khan’s Galaxy Apartments in Mumbai, according to a recent update posted on their X (Twitter) account. NIA has interrogated shooters Vicky Gupta and Sagar Pal, arrested in the firing case, the tweet said.

According to the reports, two Punjabi residents were taken into custody by the Mumbai Crime Branch yesterday on suspicion of being involved in the recent shooting incident outside the house of Bollywood actor Salman Khan.

The two men, Sonu Subhash Chander and Anuj Thapan, provided guns to Sagar Pal and Vicky Gupta, the shooters, according to information released by the Mumbai Crime Branch. It was also reported that they had communication with the Bishnoi gang. For those who don’t know, hours after the incident, Anmol Bishnoi, the brother of gangster Lawrence Bishnoi, allegedly took credit for the firing in a Facebook post.

The shooters’ custody has been extended by Mumbai’s Esplanade Court until April 29.

Meanwhile, on the workfront Salman Khan was last seen in Tiger 3 alongside Katrina Kaif.

-

2024 Lok Sabha Elections9 hours ago

2024 Lok Sabha Elections9 hours agoPM Modi calls for high voter turnout in second phase of Lok Sabha elections 2024, says your vote is your voice

-

2024 Lok Sabha Elections3 hours ago

2024 Lok Sabha Elections3 hours agoLok Sabha election 2024: Nearly 50% voter turnout recorded in second phase till 3 pm

-

India News8 hours ago

India News8 hours agoSalman Khan house firing case: NIA interrogates arrested shooters Sagar Pal, Vicky Gupta for three hours

-

2024 Lok Sabha Elections7 hours ago

2024 Lok Sabha Elections7 hours agoLok Sabha elections 2024: 102-year-old man walks to polling booth to cast his vote in Jammu

-

2024 Lok Sabha Elections2 hours ago

2024 Lok Sabha Elections2 hours agoElection Commission books BJP MP Tejasvi Surya for seeking votes in the name of religion